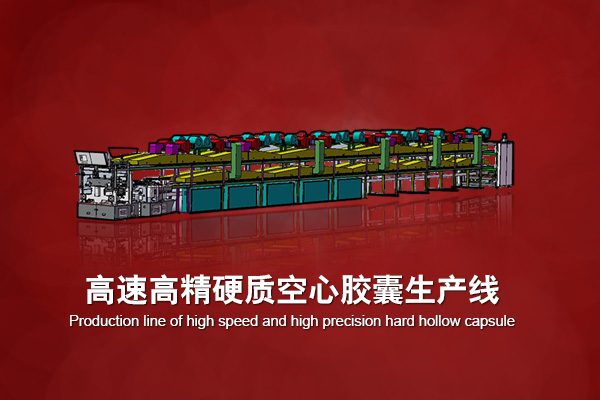

WH-SG40 high speed and high precision full automatic hard hollow capsule production line

Introduction: WH-SG40 high speed and high precision automatic hard hollow capsule production line is microstat constant Engineering Co., Ltd. with Mitsubishi currently the latest servo drive technology, upgrade the development of automatic hard hollow capsule production line, the production line set mechanical, electrical and pneumatic integration of high technology in a body, with high speed and high precision characteristics, compared with the capsule factory existing hydraulic driven production line with low energy consumption, high efficiency, clean degree higher characteristic. Companies always adhere to the "customer first, quality oriented" concept, the pursuit of excellence in product production, fine workmanship, reliable quality, products sell well all over the country.

- By the programming control module, servo motor, electric cylinder, linear module, pneumatic system and other advanced components more accurate control of the various parts of the speed and position. Instead of the traditional production line using hydraulic drive mode, completely solve the hydraulic cylinder leakage caused by oil pollution, reduce the cost of high energy consumption of hydraulic power station, reduce the maintenance time and cost of maintenance.

- In the production process not only has stepless speed regulation (without stopping), automatic regulation of slow start, fast braking, fault display and fault alarm, automatic temperature control, viscosity, automatic fault recording and production automatic counting basic functions Can also be based on user needs, the use of network control technology, can be achieved for the entire capsule production workshop so that the entire audience's information management and monitoring.

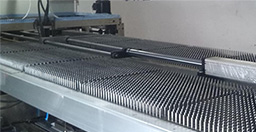

- With all types of molds are used in the most high-quality stainless steel bar processing, with the use of the latest development of our company's processing technology, The mold precision to the most advanced domestic level, supporting die can be suitable for home and abroad of various types of production lines, excellent accuracy suitable for producing all kinds of dynamic (plant) matter hard hollow capsule, while ensuring production capsule has more high qualified rate.

Main technical parameters:

- speed

- 50 plates per minute

- throughput

- 90 thousand grains per hour

- Disc diameter

- Φ111.25(mm)

- The number of plastic dip

- 6 plates or 7 plates / times

- Machine running maximum noise

- Less than 80 (DB)

WH-SG40 high speed and high precision automatic hard hollow

capsule production line control system using Japanese MITSUBISHI and Panasonic technology, using distributed control structure, maintenance

convenient and quick. User interface using touch screen, control and management of the production process to achieve on-site centralized management,

decentralized control. All the electrical components on the touch screen for parameter setting, control operation and auxiliary control of real-time data display, etc.,

with the operation is simple, easy to use, good human-computer interaction characteristics. In the normal production process, the average failure time is very short, precise control, fully meet the requirements of all kinds of dynamic (plant) material of the production of hard hollow capsules. WH-SG40 high speed and high precision automatic hard hollow capsule production line in the production process of various types of signal acquisition using intelligent control system, temperature sensor and position control module at present advanced detection means of control, very precise to complete numerical signals in the production process of feedback and positioning control, and the use of simple and easy operation, greatly facilitates the manufacturers use update adjusting process parameters and product quality control.

WH-SG40 high speed and high precision automatic hard hollow

capsule production line control system using Japanese MITSUBISHI and Panasonic technology, using distributed control structure, maintenance

convenient and quick. User interface using touch screen, control and management of the production process to achieve on-site centralized management,

decentralized control. All the electrical components on the touch screen for parameter setting, control operation and auxiliary control of real-time data display, etc.,

with the operation is simple, easy to use, good human-computer interaction characteristics. In the normal production process, the average failure time is very short, precise control, fully meet the requirements of all kinds of dynamic (plant) material of the production of hard hollow capsules. WH-SG40 high speed and high precision automatic hard hollow capsule production line in the production process of various types of signal acquisition using intelligent control system, temperature sensor and position control module at present advanced detection means of control, very precise to complete numerical signals in the production process of feedback and positioning control, and the use of simple and easy operation, greatly facilitates the manufacturers use update adjusting process parameters and product quality control.

Production line drive control mode from the past hydraulic drive, upgrade to servo motor, electric cylinder and other new actuator and intelligent control system,

More precise control of the speed and position of each part of the action. The hydraulic oil leakage and oil pollution pollution caused by the aging of the hydraulic oil cylinder sealing pad is solved, and the high energy consumption cost of the hydraulic station is reduced, and the maintenance time and the cost of the maintenance are reduced.

Production line drive control mode from the past hydraulic drive, upgrade to servo motor, electric cylinder and other new actuator and intelligent control system,

More precise control of the speed and position of each part of the action. The hydraulic oil leakage and oil pollution pollution caused by the aging of the hydraulic oil cylinder sealing pad is solved, and the high energy consumption cost of the hydraulic station is reduced, and the maintenance time and the cost of the maintenance are reduced.